Key Takeaways

- Artificial intelligence (AI) is emerging as a key enabler of a manufacturer's digital transformation. Agentic AI is poised to revolutionize supply chain management.

- As Generation Z enters manufacturing, they bring digital fluency but also new expectations for flexibility, meaningful work, and career growth.

- Workers must learn to collaborate with AI, providing clear guidance, refining outputs, and leveraging AI as a co-creator to maximize efficiency and adaptability.

Listen: The enormous tech wave and its impact on manufacturing.

The manufacturing industry is undergoing a seismic shift, driven by advanced technologies and next-generation production practices. Manufacturers are increasingly adopting robotics, the Internet of Things (IoT), and digital twins to enhance efficiency and automation. This raises an essential question for the future of the industry—how will AI affect manufacturing? The goal is to build highly connected smart factories that, as the Manufacturing Leadership Council states, “will enable real-time data analysis and optimize production processes across the entire manufacturing lifecycle.”

AI is emerging as a key enabler of this transformation. In a recent manufacturing study, 35% of respondents already use generative AI to improve their customer experience in the front office; while 44% plan to invest within the next three years. By 2026, nearly half of manufacturers are expected to integrate AI into their production facilities, underscoring AI’s growing role in driving efficiency and innovation.

Unique challenges in industrial manufacturing

As digital transformation accelerates, it brings unique challenges across people, processes, and technology. Navigating these complexities is crucial to fully realizing the benefits of advanced manufacturing.

The Manufacturing labor shortage

In the third quarter of 2024, nearly 60% of manufacturers cited the inability to attract and retain employees as their top challenge. While labor markets have eased in other industries, manufacturing continues to face a rapidly evolving workforce with shifting skills and expectations.

Manufacturers have built up their industrial might over the decades, owing to a strong and loyal workforce. In aerospace and defense manufacturing, for example, one-third of employees are 55 and older. Now, a new generation of employees is stepping in. Generation Z—dubbed the “Toolbelt Generation” because of their willingness to work with their hands—offers fresh potential. Keeping them on the job won’t come easy, however, as Gen Z expects workplace flexibility, meaningful work, and career advancement.

This generational shift presents an opportunity. With an innate grasp of digital technologies, younger workers could help accelerate the adoption of augmented reality (AR), virtual reality (VR), and extended reality (XR) for enhanced productivity. Regardless of whether employees are long-tenured or newly hired, manufacturers must invest in training that blends traditional technical skills with advanced digital tools to remain competitive.

Reimagined workflows and supply chain

Throughout manufacturing, higher-level skills could grow the fastest between 2022 and 2032. As economies consider building and securing the manufacturing workforce of the future, the scenarios will consist of workers who can process data faster and derive smarter insights with AI copilots at their side. The World Economic Forum notes that “data and analytics allow frontline workers to make informed decisions in real time, creating dynamic processes that adapt to evolving conditions.”

New User Interfaces created by Gen AI

Manufacturing is becoming more tech-driven; having intuitive and efficient user interfaces is essential for seamless operations. Generative AI is transforming user experience (UX) design by automating wireframing and refining layouts to enhance usability.

For example, many designers use Figma, which has templates, plugins, and user interface (UI) kits. AI plugins are available to help designers incorporate key features, optimize functionality, and tailor interfaces for specific user needs. Additionally, generative AI adapts designs for mobile devices, ensuring they align with how modern users interact with digital tools. These advancements make manufacturing interfaces more accessible, responsive, and user-friendly.

The future of manufacturing

Agentic AI

Across industries, agentic AI is being introduced to enable autonomous decision-making. These AI systems execute complex tasks, interact with other AI agents, and optimize processes—freeing people to focus on high-value strategic decisions that drive business growth.

So, how will AI affect manufacturing? Agentic AI is set to revolutionize supply chain management. AI agents can autonomously analyze market conditions, compare vendors, select partners based on predefined criteria, and oversee contract performance. They can track shipments, manage supplier relationships, and continuously refine procurement strategies—creating a more efficient, adaptive, and resilient supply chain.

It’s also important to note that not all AI systems work the same way. Some act like automatic sensors, instantly reacting to environmental changes. Others are more strategic, analyzing data, planning steps, and taking action to achieve a goal. The most advanced AI learns from experience, adjusting and improving over time to make even smarter decisions.

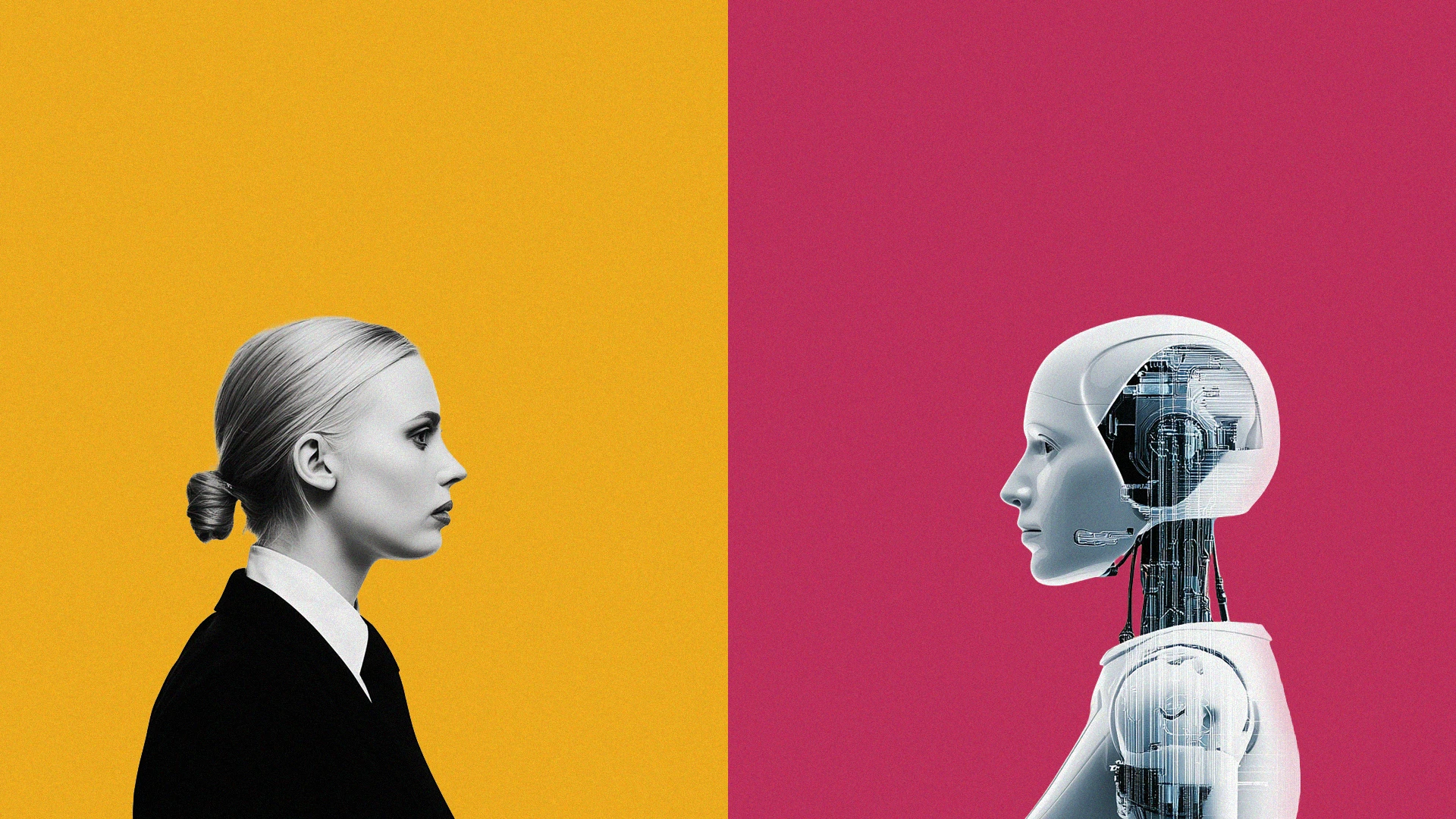

The human-AI balance

As AI takes on more responsibilities, the challenge will be striking the right balance between human creativity and AI-driven efficiency. This shift is fundamentally about skills. Generative AI in manufacturing will play a pivotal role in this evolution, with employees across all levels of the organization collaborating with large language models (LLMs) like OpenAI’s ChatGPT, Anthropic’s Claude, and Google’s Gemini to enhance productivity and innovation.

In manufacturing, finding the right balance between AI and human skills is key. AI can handle data, streamline production, and automate tasks, but people are still needed to solve problems, think creatively, and adapt when things don’t go as planned. Workers will need to learn how to work alongside AI, using it as a tool to make their jobs easier and more efficient. The integration of AI will undoubtedly spark new levels of manufacturing innovation, as manufacturers combine smart technology with skilled employees to stay ahead, producing better results while keeping quality and creativity strong.

In manufacturing, finding the right balance between AI and human skills is key. AI can handle data, streamline production, and automate tasks, but people are still needed to solve problems.

To maximize AI’s potential, workers must become skilled co-creators. People will learn to give the AI clear instructions (what is known as “prompt”), discern when to step in if the output doesn’t seem right, and train the AI to refine its capabilities and tackle even bigger manufacturing challenges ahead.

Riding the tech tsunami

Manufacturing stands at the crossroads of an unprecedented digital transformation. Advanced technologies and next-generation practices are reshaping every aspect of the industry, from supply chains to workforce dynamics. This digital transformation in manufacturing movement isn’t just a trend—it’s revolutionizing how companies operate and compete. While challenges exist, the opportunities to innovate, optimize, and redefine processes far outweigh the obstacles. The question is no longer if manufacturing will adapt but how fast it can ride this unstoppable wave of transformation. Those who embrace the shift will lead the future of a smarter, more connected, and more resilient industry.

Navigating these changes and integrating new technologies successfully can be complex. Partnering with the right experts can make all the difference. Aquent is here to help you stay ahead, providing the guidance and support needed to fully leverage innovation and thrive in this new manufacturing landscape. Reach out today to find the expertise you need to transform your operations with confidence.

Latest.

Win the 2026 talent race in Canada’s creative sector.

Leadership & Management, Retention Strategies, Talent Acquisition & Recruitment

AI is silently driving the wage gap, here’s how to fix it.

Diversity, Equity & Inclusion, Leadership & Management, Retention Strategies, Innovation & Emerging Tech, Talent Acquisition & Recruitment

10 proven strategies to streamline marketing operations in 2026.

Leadership & Management, Consulting & Operations, Marketing & Analytics